When you factor in storage fees, shrinkage, and obsolete products, the annual additional cost of holding excess inventory can be as much as 32%. For businesses of all sizes, the trick is to reduce your inventory costs while guarding against a disastrous stockout.

We’re going to take a look at what the JIT method involves, the pros and cons, and why it’s important to use a system with advanced inventory management like Brightpearl to stay on top of stock levels and supplier management.

What is Just in Time Inventory?

Just in Time (JIT) is a method of inventory management in which you keep your stock levels as low as possible. The aim is to reduce storage costs and improve cash flow. You don’t order new products until they are required—because a customer has requested them, or because you’ve sold out.

You have to work closely with suppliers so that goods arrive exactly when they are needed (“just in time” to meet demand). To make JIT work, you need a super-reliable supply chain and robust inventory management software with highly-accurate demand planning. Without this, the system will fall apart and you’ll run the risk of stockouts.

JIT is known as a lean management technique, in which all processes and people involved in the system (from production line to delivery) are interconnected and mutually dependent. The idea is based on Kaizen, a Japanese term meaning “change for the better”, and sees everyone pulling together for success.

Source: sketchbubble.com

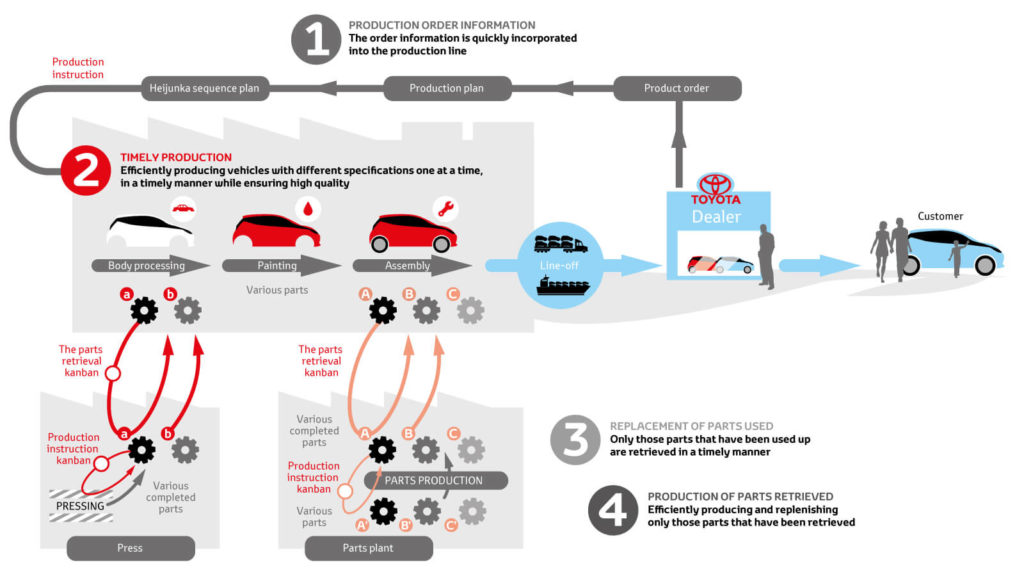

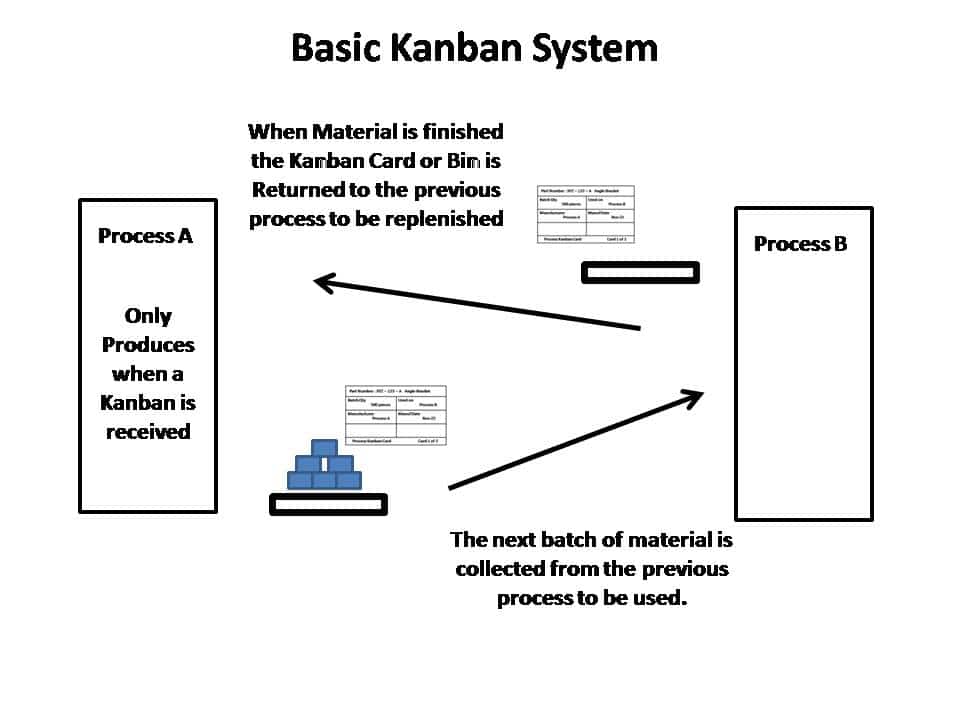

This system typically uses Kanban (Japanese for “sign”), an inventory control system that involves tracking materials as they run out. It also focuses on streamlining and optimizing organization and communication—with continuous improvements to ensure high quality and customer satisfaction.

The just-in-time methodology originated in Japan in the wake of World War II, when the car manufacturing industry was facing shortages. Toyota knew it had to minimize resource consumption to survive, and developed a form of JIT known as the “Toyota Production System” (TPS). This had a worldwide influence on companies driven by mass production.

We should point out that JIT inventory and JIT manufacturing are somewhat different. Just-in-time manufacturing focuses on adding value to the production process, and only makes what customers order. JIT inventory is all about cost reduction—you order and receive just enough materials to create, or pack and deliver, the goods required to meet customer demand.

Just in Time vs. Just in Case Inventory

As we’ve seen, JIT aims to reduce the costs and waste associated with excess inventory levels. Instead of filling your warehouse with goods and raw materials, you keep the bare minimum of stock on hand, and use smart forecasting to predict demand.

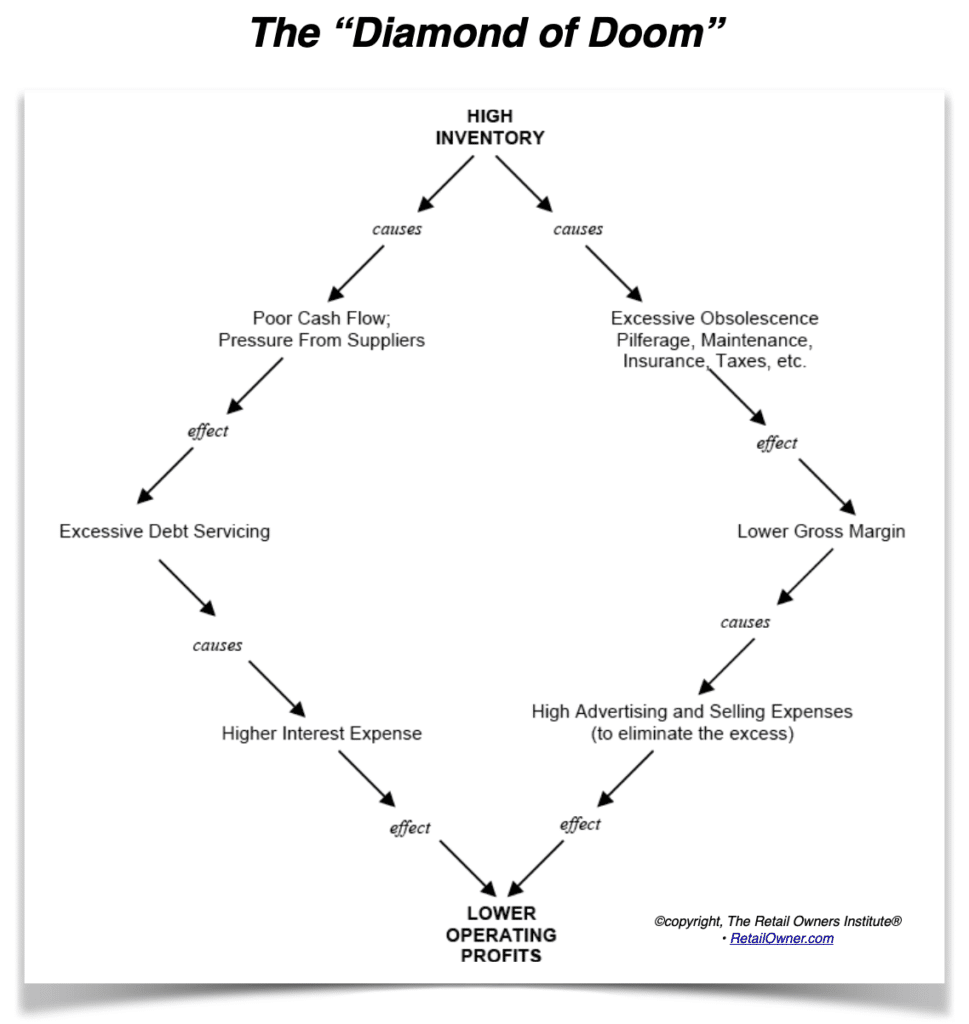

The polar opposite of this strategy is the Just In Case inventory method. As you might imagine, this involves ordering and holding large amounts of surplus goods (or “safety stock”) just in case it’s needed. This belt-and-braces approach ensures that you can fulfill orders on time, even if there’s a sudden surge in demand or a supply chain problem.

If you’re a retailer that depends on seasonal sales, or your business relies on getting hold of raw materials or natural resources that may prove hard to find, the JIC method could benefit you.

Preventing stockouts and backorders helps your business meet customer expectations and maintain a good reputation. But on the flipside, the high cost of purchasing and storing inventory will put a dent in your profits, as well as increased spoilage and obsolescence of inventory.

Source: retailowner.com

Industries That Use Just in Time Inventory

Both retailers and lean manufacturing businesses use the JIT inventory model. It’s most suited to established businesses with a robust supply chain, but a low-budget business with limited warehouse space may also choose this approach. Either way, you’re going to need a software solution like Brightpearl to help you make JIT work.

Fashion

In the fashion industry, you need to offer a wide variety of styles, sizes and colors in order to entice customers and maximize sales. This generally means carrying more inventory, which leaves you with high storage costs—as well as the risk of being left with dead stock if an item doesn’t sell or goes out of fashion.

That’s why JIT inventory is useful for small e-commerce businesses and major fashion retailers alike, as you can use demand forecasting to produce or procure the right amount of apparel or accessories. For example, data from previous years will tell you the optimum times to order beachwear or Christmas-themed items.

JIT is particularly useful for “fast fashion” companies such as Zara, which owns its supply chain and is able to bring goods to market in double-quick time. Because the firm designs and manufactures up to 50% of its range in mid-season, it can react fast to new trends and get items into stores before the bandwagon rolls on.

Publishing

JIT inventory management is also widely used in the publishing industry, especially by small independent publishers and authors who choose to self-publish their work. This approach is also known as on-demand publishing.

When budget is a concern, it makes sense to only print and assemble the right quantity of books needed to meet order fulfillment. Not only does this reduce the cost of production and inventory storage, it also cuts down on wasted paper and the sorry sight of unsold books being pulped.

Source: toyota-europe.com

Automotive

As we saw earlier, the JIT method was actually developed in the automotive industry—and it’s still widely used by vehicle manufacturers who want to streamline their operations by making only what demand requires. The advantage is that production costs are kept low while production quality remains consistently high.

Toyota is still one of the best-known exponents of the JIT method. It only orders raw materials and parts when a customer places an order, and only receives them in the factory when it is ready to start building the car. Harley-Davidson also used just-in-time manufacturing principles to reduce inventory levels by 75% and increase productivity.

Food

Supermarkets are a classic example of JIT inventory management—as shoppers take grocery items off the shelf, employees replace them with enough new stock to fill the gaps. Smaller stores and those that specialize in fresh food also use JIT, as it enables them to order small batches of food more frequently—instead of storing large quantities in freezers for long periods of time.

Another example is the fast food industry, where franchises typically cook and assemble meals only when orders are placed, rather than serving pre-prepared and reheated food. While they need to keep a certain amount of ingredients on hand, they can use demand planning to predict busy and slow times, thus reducing waste.

Characteristics of JIT Inventory System

The JIT inventory system is characterized by certain practices that help to keep it running smoothly. Here are the major elements:

Smaller Deliveries

Since you’re keeping less inventory in stock, you’re not going to need huge trucks delivering a ton of pallets to your warehouse or distribution center. In JIT, it’s all about smaller deliveries received more often. These might arrive daily or even hourly, to fit in with your processes and keep up with demand.

You may be thinking that having more deliveries will cost more, when the whole idea is to reduce spending on inventory. But this should be outweighed by the other benefits, including lower storage costs. You can mitigate delivery costs by using smaller trucks—and if your suppliers are local, one truck could visit multiple suppliers in one trip.

Higher Supplier Quality

The JIT method depends on a network of trusted suppliers, who are usually certified for quality. This means you can guarantee that the materials and goods they send you are up to scratch—and you won’t have to carry out a full inspection each time a delivery arrives.

Therefore, deliveries can be transferred immediately to the picking and packing areas, instead of being held in the receiving area. It’ll free up space in your facility as well as saving time (and enabling staff to get on with other tasks).

JIT also depends upon maintaining strong communication and relationships with suppliers, so it’s good to have a software solution that helps you manage them all in one place—such as Brightpearl, which even gives them access to a shared web portal.

Work Arrangements

JIT aligns production schedules and fulfillment processes with the delivery of supplies for a continuous flow of work, and focuses on reducing the amount of time between receiving and delivery. This means you need to pay attention to the layout of your warehouse, so that goods can be passed quickly and efficiently between work centers.

Source: leanmanufacturingtools.org

Because you’re working with smaller inventory, these work centers can be smaller and closer together. You can also use optimization strategies such as batch picking and zone picking, and placing best-selling products nearest to packing stations.

JIT users often employ the Kanban system, which uses cards (digital or paper) to track the progress of goods, signal when it’s time to order more stock, and keep the entire team informed of inventory levels.

Cross-trained Employees

One of the aims of JIT is to optimize your human resources, and employees in this system are often “cross-trained” to work on a variety of tasks. This cuts down on idle time, as there’s always something to do—and the business can reduce costs by getting more work done with fewer staff.

Workers with diversified skills can quickly be deployed to different areas where they are needed most, in order to keep processes moving. Another advantage is that it encourages team empowerment, and helps staff stay committed to the shared success of JIT.

Fulfillment upon Completion

If you’re using JIT, you won’t need much storage space for completed goods or materials. As soon as your workers finish assembling and/or packing the product, it is immediately placed on a truck for shipment to the customer. This improves efficiency and saves on storage costs, as you don’t need to have a separate area for goods waiting to be shipped (and packages won’t hang around long enough to get lost or damaged).

Automated systems (such as Brightpearl’s Automation Engine) are useful here—tools like barcode and RFID scanners make it easy to locate the right products, and if something’s out of stock then you can quickly check availability with the POS tool and opt to fulfill the order from another location.

Advantages of Just in Time Inventory

We’ve discussed the major advantages, but here are a few more to consider:

Minimize Waste

If you hold large amounts of inventory, there’s always the worry that it won’t sell and you’ll be left with obsolete stock—and the money you forked out for warehouse space and insurance will be wasted. But JIT massively reduces that risk, as you’ve already figured out that there’s enough demand for the goods you order.

Carrying smaller numbers of items at a time means there’s less chance of losses through accidental damage or spoilage of fresh goods (remember it’ll cost you to scrap them), or due to theft. It’s also much easier to identify any defective items when inventory levels are low, and you’ll have the agility to abandon products that are no longer selling well.

JIT also helps you minimize wasted time, by speeding up processes like receiving, putaway, and cycle counts. This increase in productivity will reduce labor expenses, especially since shorter turnarounds and accurate forecasting mean that extra help is less likely to be needed.

Cash Flow

Minimizing the amount of inventory on hand gives you more freedom in terms of cash flow, as you’ll have less working capital tied up in the various costs of purchasing, storing, and replenishing stock. You’ll also save on labor costs, as it takes fewer staff to manage a minimal inventory.

Local sourcing of goods is another way to reduce expenditure and free up extra cash. If your suppliers are located nearby, the goods you order have shorter distances to travel—meaning they should always arrive when you need them.

By spending smaller amounts on these aspects, you can allocate more money to other business costs such as marketing. Although you need less cash on hand in JIT, you still need to have some in reserve in case of unexpected events.

Better Professional Relationships

Whether it’s inventory management or the manufacturing process, JIT helps you get finished products to the consumer as fast as possible. Customers have come to expect speedy delivery times, so the ability to meet those expectations will lead to improved customer satisfaction (translating into brand loyalty and more sales).

It’s also easier to delight your customers by offering bespoke or customized products, on an on-demand basis. This wouldn’t be possible if you were ordering inventory in bulk.

But it’s not just about customers—JIT principles encourage businesses to focus on quality control and continuous improvement, which means that your distributors, retail partners, and stakeholders will develop greater confidence and trust in your services.

Disadvantages of Just in Time Inventory

Yes, there are a few downsides to the JIT inventory strategy—but you can mitigate against most of these by optimizing your business for this new way of working.

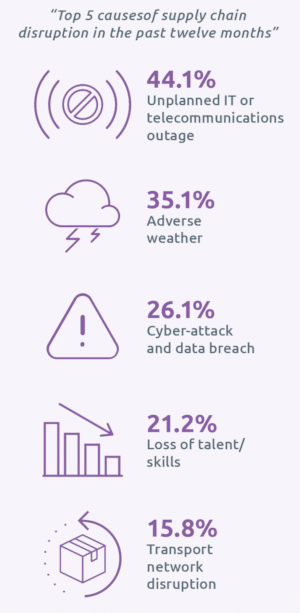

Supply Chain Breakdown

Just In Time inventory management requires suppliers and retailers to be in perfect sync, with goods delivered on time every time. You can run into problems if there’s any disruption to the supply chain. If a supplier is unable to deliver as promised, you’ll end up with a stockout—which can have a drastic impact on customer satisfaction.

For example, if your warehouse does kitting, and a supplier fails to deliver one of the components, you won’t be able to complete the product. In the worst-case scenario, you might even have to shut down your operations for a few days. And stockouts cost money: for example. Gap estimated that it had lost $300 million in a single quarter due to inventory stockouts.

Although major global supply chain breakdowns are beyond your control, you can reduce the chance of problems by developing good relationships with local suppliers and streamlining your supply chain management.

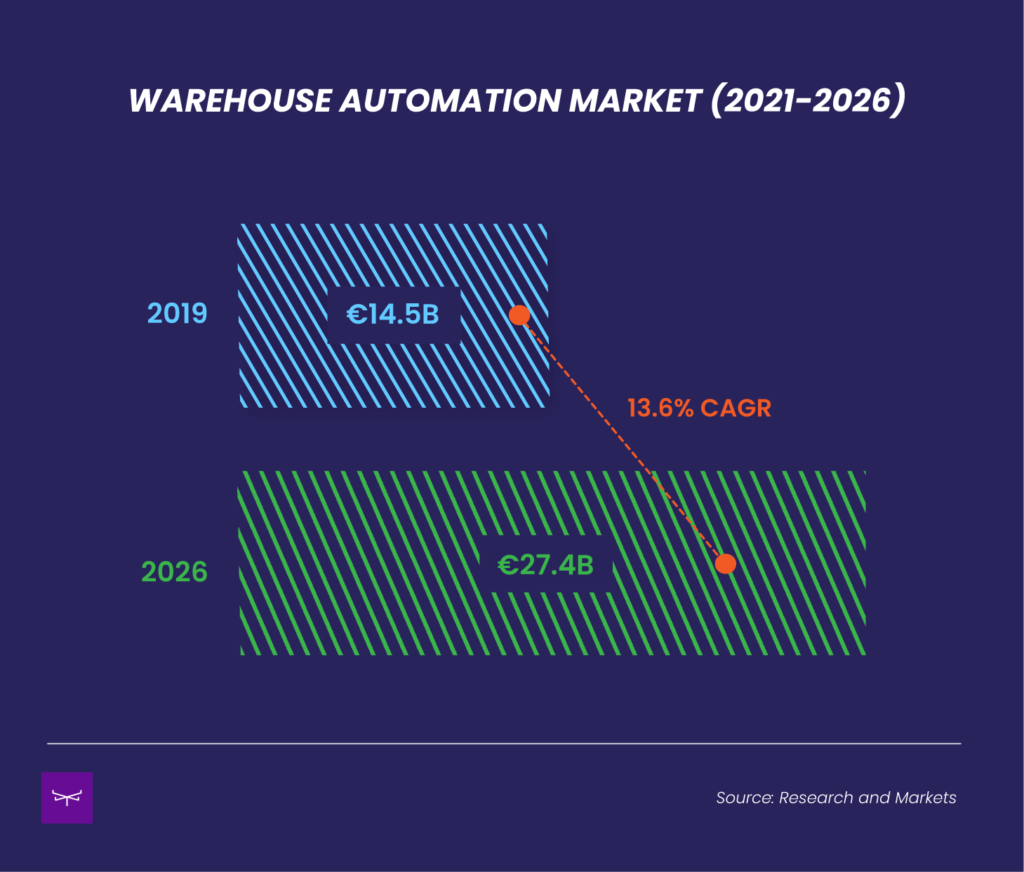

Source: thebci.org

Prices of Inventory Fluctuate

Another downside of JIT is that you’re at the mercy of price fluctuations. The cost of inventory can go up or down based on multiple external factors, and there could be an increase right at the moment when you need to place a big order. Large companies should be able to cope with this (particularly as the JIT method frees up cash flow), but for smaller businesses, a sudden price hike can really affect your bottom line.

You also have less flexibility on pricing. JIT relies on you replenishing stock as soon as it’s sold, with no room for delays—so you can’t shop around for the best deal or wait until the price of materials drops. If your supplier decides to charge more than usual, there isn’t much you can do about it.

Organization

Implementing the JIT strategy is complex—you need to rethink the entire workflow of the business and design all your processes to fit the JIT model. If your company is not well-organized, the system will soon break down.

In JIT, there is no margin for error. You don’t have safety stock to rely on, so you need to keep a close eye on the inventory you do have to make sure it’s all where it should be and in the right condition. If you don’t know exactly what you have, you won’t be able to react quickly to unexpected orders.

It’s important to use a software solution that gives you real-time visibility of your inventory, as well as the means to make precise forecasts. To keep the whole process running smoothly, it should also cover purchasing and order management, and integrate with other business systems like CRM and accounting.

Best Practices in Implementing Just in Time Inventory

We’ve put together a few top tips for making JIT work for your business.

Good Relationship with Suppliers

For the JIT method to be effective, it’s vital that you develop strong relationships with reliable suppliers. You can’t run the risk of slow production or inconsistent delivery—you need total confidence that the goods you ordered are going to arrive exactly when you need them.

Communication is key, so make sure you share as much information as possible with your partners and encourage them to do likewise. That way, you’ll all have a clear idea of the current situation and can put contingency plans in place if necessary.

It’s good to use local suppliers if you can, since they’ll be able to deliver your orders faster and you’ll save on transportation costs (and it’s better for the environment, too). Don’t forget that you need equally good relationships with shipping carriers, which is something that Brightpearl can help with.

Train Your Employees

As we mentioned earlier, JIT requires you to have cross-trained employees with diverse skill sets so that they can switch roles seamlessly and be deployed to any part of the operation. You may be able to hire staff who already have these skills, but it’s likely that most workers will need some training on the processes specific to your business.

Again, regular and clear communication is a must, not just in terms of sharing info with suppliers and shipping partners but also between management and the warehouse team. You should foster a culture where everyone knows the importance of keeping their colleagues updated and acting quickly if there’s a problem.

Your employees will also need the best tools to maximize their productivity. For example, things like barcode and RFID scanners for quick location of products, and auto-generated packing slips and shipping labels. They will require training to make sure they can operate the software effectively.

Keep Production Operations Stable

We’ve already discussed the need to optimize your business so that you can maximize the potential of JIT. This includes developing production plans, such as optimum production lot sizes and lead times, and sharing this information with your suppliers.

It’s also important that you stick with your plan—if you change the system at the last minute, your supplier may not be able to deliver on time. They need to have a clear idea of your demand, which is why JIT requires accurate planning. Tracking sales data will help you spot likely fluctuations and seasonal trends, so that you can time your orders with precision.

Delegate Responsibility to Workers

To make a success of the JIT method, you need full buy-in from everybody involved. Your whole business should be committed to the JIT principles, with all sectors working together in harmony. It’s crucial that everyone understands the benefits of JIT and how their role fits into the big picture, as well as knowing exactly how the processes should work.

This culture also depends on management being willing to delegate responsibility to workers on the shop floor. If leaders are reluctant to give up control, they can end up micromanaging employees and getting overwhelmed by tasks that could easily be handed to someone else.

It’s much better to empower the people who are handling your day-to-day operations, letting them play to their strengths and encouraging their input and feedback. Remember, JIT is all about continuous improvement—and who better to spot any problems than the workers at the coalface?

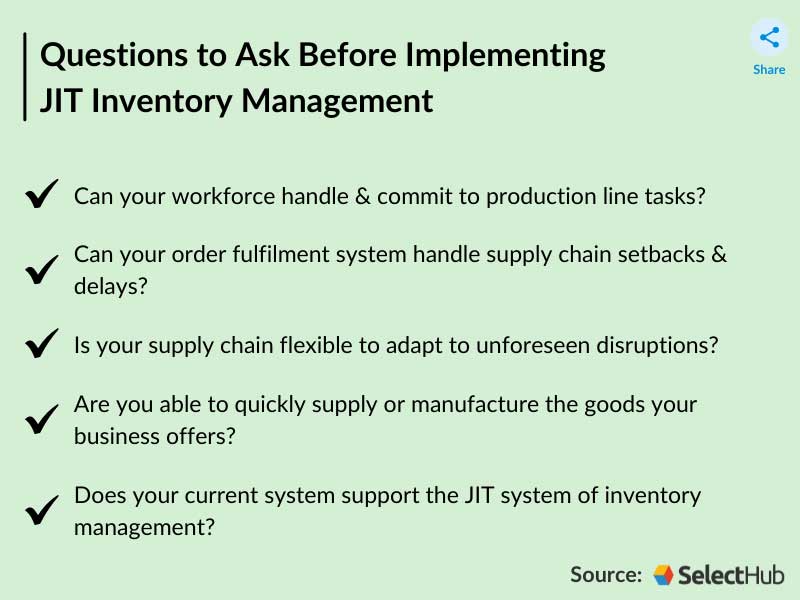

Is Just in Time Inventory Right For You?

Implementing the Just In Time inventory method takes time and effort, so before you decide to go down that route, you need to check whether or not it’s right for your business. Your entire organization has to be ready to make the switch, which means you need confidence in suppliers and forecasts, a committed workforce, and the latest technology.

JIT generally works best for established businesses, because they have already spent many years developing a smooth production and supply chain process, and they have plenty of data to use for forecasting consumer demand.

However, newer companies with budget constraints and a lack of storage space may also choose to use JIT, because it allows them to place smaller orders and free up cash flow. If your company has low inventory, small batch sizes, or a non-complex supply chain, JIT could still be a good fit for you—as long as you can find reliable suppliers.

Here’s a checklist of the elements you should have in place before signing up to JIT:

A Robust Supply Chain

Make sure you work with suppliers who have consistent production schedules and guaranteed high-quality products, so that you don’t have to spend time inspecting every batch. Maintain close working relationships through constant communication, which will help you head off any potential problems in advance.

Smooth Management

Ideally, you need a system for managing all your suppliers in one place, with easy access to information on payments and schedules. And you also need the ability to manage your shipping carriers and third-party logistics providers, so that every stage of the supply chain runs like a well-oiled machine.

Steady Demand for Products

JIT works best when there’s minimal variability, so it’s a good fit for businesses with steady customer demand. If your company experiences a lot of fluctuations in demand, for instance with seasonal products, then another inventory method may work better for you.

Precise Forecasting Capabilities

In order to keep the supply chain running smoothly, you need to plan as far in advance as possible. Although your suppliers will only deliver when a customer order is placed, they still need to know the likely time frame for these orders.

This is where you need accurate forecasting, using tools like Brightpearl’s Demand Planner to show you exactly when, where and what to reorder. You can harness your sales history, set the right budget, and get an insight into which products are selling well and which aren’t.

Efficient Systems and Processes

As well as a strong cross-functional workforce, JIT will work best when you have a highly efficient customer order fulfillment system in place. This includes automation for picking, packing, shipping, generating purchase orders and invoices, and organising replenishment. Keeping track of suppliers is also key.

The Right Software Solution

In order to accomplish all these things, it’s crucial that you choose the right software for the job. Believe it or not, there are some businesses out there still using manual-entry spreadsheets for inventory control and tracking—but that’s just not viable in the fast-moving world of JIT.

Because the just-in-time method requires precision, you need full control over your part of the supply chain. Look for a solution that combines inventory management software with order management and fulfillment capabilities, as well as robust analytics to help you monitor sales and predict demand.

Although JIT helps you reduce the amount of inventory you hold, it’s still vital to maintain full visibility into your stock. 43% of retailers say that enhanced stock level visibility would help them better serve customers and increase the overall customer experience (and happy customers lead to increased sales).

Final Thoughts

When done correctly, JIT increases efficiency and lowers the cost of warehouse storage—as well as reducing the risk of problems associated with excess stock. The philosophy of continuous improvement also leads to higher-quality products and faster response to customer feedback in future production cycles.

However, this method means you have to tread a fine line between holding exactly the right amount of inventory and not having enough to fulfill your orders. To avoid stockouts, you need to work with reliable suppliers and keep a close eye on stock levels at all times.

Brightpearl’s retail-focused operating platform helps you do all that and more, with automation to streamline your processes and advanced demand planning to ensure you procure just the right amount of stock—and order it just in time.